Volvo Trucks has developed a way of harnessing heat energy from brakes and using a vehicle’s momentum to save energy.

It calls the system I-See, which operates like an autopilot and takes over gear changing and utilises gradients to save fuel.

When a vehicle brakes its kinetic energy is converted into heat. Many manufacturers in the automotive world are now examining solutions for harnessing kinetic energy instead of releasing it as surplus heat. "If kinetic energy can be exploited to a greater extent, it may help cut fuel consumption. This will benefit both the environment and the industry's economy, something that is very important today as fuel costs are becoming an increasingly heavy burden on many haulage firms," said Anders Eriksson, Product Developer at Volvo Trucks.

And it is precisely this that Volvo Trucks has succeeded in developing with its new I-See solution. The system harnesses the truck's own kinetic energy to ‘push’ the vehicle up hills. On downhill gradients the same energy is used for acceleration.

Kinetic energy can save 5%

Kinetic energy can save 5%

I-See is linked to the transmission's tilt sensor spot hills before it reaches them. The fact that the system is not dependent on maps makes it more dependable since it always obtains the very latest information. I-See can recall about 4,000 gradients, corresponding to a distance of 5,000 kilometres.

"I-See is an autopilot linked to the truck's cruise control, taking over and handling gear changes, throttle and brakes on gradients, ensuring they all operate in the most fuel-efficient way possible. I-See freewheels as much as possible - so on certain stretches of road no fuel is used at all," explained Hayder Wokil, Product Manager at Volvo Trucks. "In this way fuel consumption can be cut by up to 5%." said Hayder Wokil.

Biggest effect on small hills

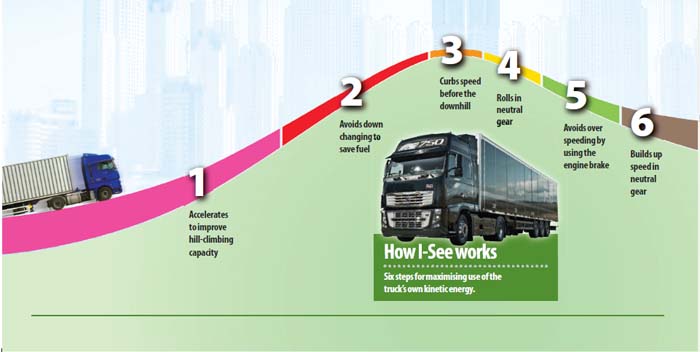

I-See carries out six different operations to utilise the kinetic energy to the very maximum. For instance, I-See accelerates up hills, remains in a high gear for as long as possible and freewheels on descents to exploit the truck's weight as a propulsion motor.

"I-See works best in undulating terrain allowing drivers to freewheel for long distances without using the engine," explained Anders Eriksson. "It is this freewheeling capability that makes the system special," he added. “But to freewheel, a whole lot of data is required. For instance, you have to know whether your speed will drop or increase over the next stretch of road. A gradient of just a few per cent can be the decisive factor."

"I-See works best in undulating terrain allowing drivers to freewheel for long distances without using the engine," explained Anders Eriksson. "It is this freewheeling capability that makes the system special," he added. “But to freewheel, a whole lot of data is required. For instance, you have to know whether your speed will drop or increase over the next stretch of road. A gradient of just a few per cent can be the decisive factor."

Other factors that make a difference are air resistance and the truck's weight. "I-See imitates the driving style of good drivers. They utilise the vehicle's kinetic energy, accelerate in time and avoid unnecessary gear changing," said Hayder Wokil. “But unlike a driver, I-See never gets tired - it's like an autopilot. It allows the driver to focus more on the surrounding traffic and other aspects of the journey.”

Anders Eriksson also pointed out that it is not only fuel that is saved. "I-See reduces brake and tyre wear and that naturally benefits the environment," he said.

I-See will become available on the market in 2013.

Photo: Six steps for maximising use of the truck's own kinetic energy.